KFlow

K-FLOW was established in 1989 in Taiwan, and well-known in the design and fabrication of Filtration and Separation equipment including Pipeline Strainers, Process Liquid & Gas Filters, Aviation Fuel & Oil Filtration & Separation micro-filters, filter water separators and Automatic self-cleaning filters, etc. Engineering uses Autocad 2015, Solid Work 2008 & Compress 2017 in the design and validation of product. Certification includes ISO 9001, ASME U2 Certificate & CE Certification.

K-Flow are in technical collaboration with Faudi Aviation of Germany.

Razvalve Pacific Pty Ltd is the exclusive channel for the sales/marketing office of K-Flow Taiwan, based in Melbourne, Australia.

Production range

K-Flow’s filtration & separation equipment are either cast, fabricated or forged and available from sizes 1/2″ up to 24″ in Class 150, Class 300, Class 600, Class 900 & Class 1500 ratings.

Standard materials offered are carbon steel WCB or A105, stainless steel 316 or 304 and other materials such as Alloy 20/CN7M, Hastelloy C, Duplex and Super Duplex.

In the Oil & Gas Industry, an efficient filtration/separation system is critical to the reliability and performance of the physical assets that process gas and petroleum products e.g. air & gas, liquid, vessels, separators, compressor protection, solids.

In the Water Industry manual & automatic fluid strainers, e.g. cooling systems, screening & straining, efflulent, irrigation, sewerage, steel plants.

Widely used in mining & processing, aviation fuel and aircraft re-fuelling, offshore oil & gas, fuel depots, pulp & paper, general industry, defence & marine, food & beverage, etc.

- 2-0-1 General Brochure-R1

- 18-1 Article Advantage Of SCF Scraper Type Self-Cleaning Filter

- 2-15-Flow Measurement

- 2-14-4 SCF Plate Type

- 2-14-3 SCF-Automatic Self-Cleaning Filters

- 2-14-2 ABW-Automatic Back-Flushing Filter (E)-R3

- 2-14-1 ABF Automatic Self-Cleaning Filter

- 2-13-1 FWS Filter Water Separators

- 2-13-0 MF Micro-Filters

- 2-12 Coalescing Filter

- 2-11 Gas-Filtration Products

- 2-10 PL High Flow Cartridge Filter-E-R4

- 2-9-3 Smart Strainer-E

- 2-9-2-2 SF Series Cartridge

- 2-9-2-1 New-Pleated Membrane Filter Cartridge Series

- 2-9-1 Cartridge Filter-E-3

- 2-8-4 Pressure Drop Diagram

- 2-8-3-1 Sanitary Bag Filter

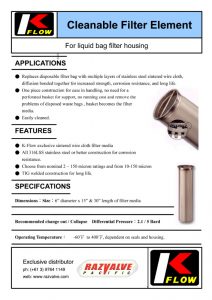

- 2-8-2 Cleanable Filter Elements

- 2-8-1 Bag Filter-E

- 2-7 ILS-In-Line Strainer

- 2-6-2-DFSS-Duplex Basket Strainer

- 2-6-1 DS Duplex Basket Strainer

- 2-5-2-FSS Fabricated Basket Strainer

- 2-5-1 CB Cast Steel Bucket Strainer

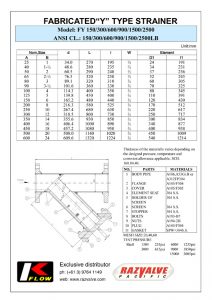

- 2-4-2 Y Strainer Fabrecated- FY

- 2-4-1 Y Strainer-CY Casted 15-300

- 2-3-4 TAM150

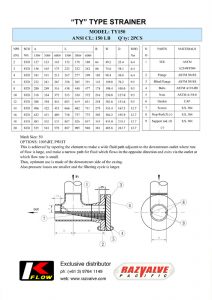

- 2-3-3 TY Strainer

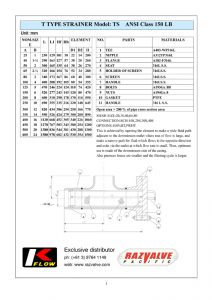

- 2-3-2 TS

- 2-3-1 TB T TYPE strainer

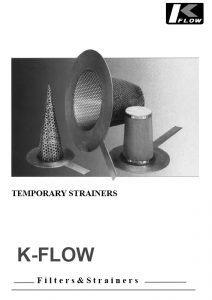

- 2-2 Cononical Type Temporary Strainers

- 2-1-0 Pipeline Strainer

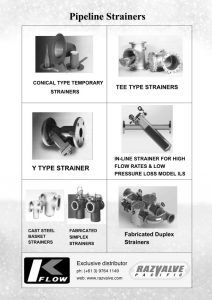

Pipeline Strainer

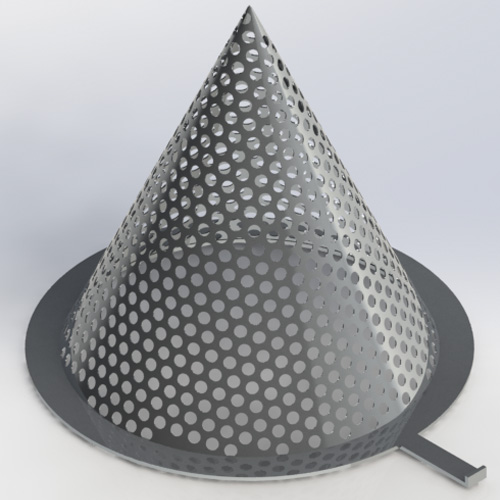

Conical (Temporary) Strainer

Size: 1-1/2” ~ 24”

Type: FT1, FT2 & FT3

Material: Carbon Steel, Stainless Steel 304, 316

Pressure / Temperature Rating: ANSI Class 150 ~2500 LB

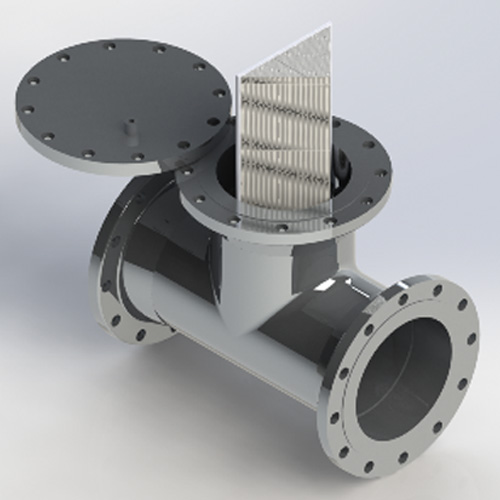

T-Strainers

Size: 2” ~ 24” Type: TB , TS , TY & TAM

Material: Carbon steel , stainless steel 304 , 316

Pressure-Temperature Rating: ANSI 150 ~2500 LB

Special material & sizes upon request

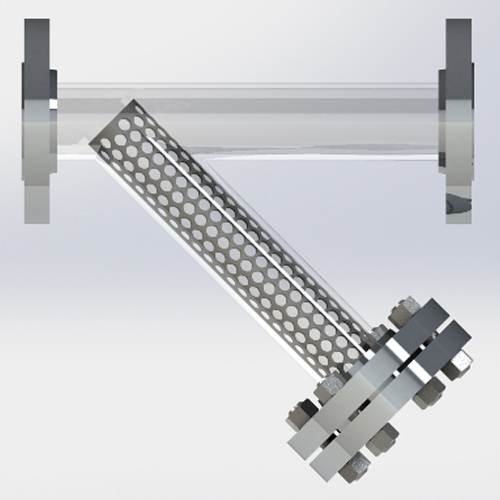

Y-Strainers

Size: 1/2”~24” Casted, forged & fabricated

Material: Carbon steel, stainless steel, alloy steel, Teflon lining, FRP, etc .

Pressure / Temperature Rating: ANSI 150~2500 LB

Special material & sizes upon request.

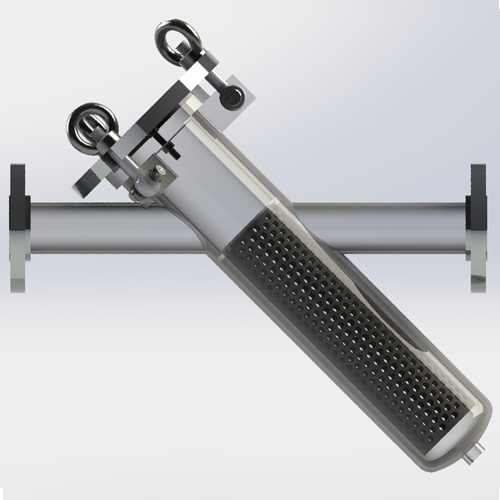

In-Line Strainer

Size: 2”~8”

Type: ILS

Material: Carbon steel, stainless steel 304, 316L

Pressure-Temperature Rating: ANSI 150~300 LB

Special material & sizes upon request.

For high flow rate & low-pressure loss

Eye-Nut bolted cover for easy maintenance & available for semi-automatic operation

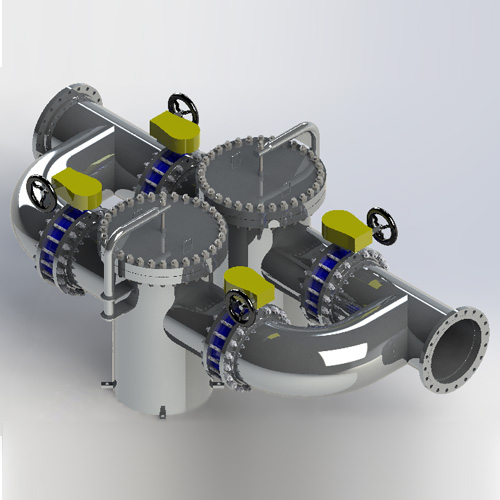

Duplex Bucket Strainer

ASME Sec. VIII code design, Cast and fabricated

Size: 2”~24”

Material: Carbon steel, stainless steel, alloy steel, Teflon lining, FRP, etc.

Pressure / Temperature Rating: ANSI 150 ~ 600 LB

Special material & sizes upon request.

Simplex Bucket Strainer

ASME Sec. VIII code design, Casted and fabricated

Size: 2”~42”

Material: Carbon steel, stainless steel, alloy steel, Teflon lining, FRP, etc .

Pressure / Temperature Rating: ANSI 150~2500 LB

Special material & sizes upon request.

Resin Trap

Suitable for line sizes up to 14”

Suitable for flow up to 360 m3/h

Material Stainless steel 304/ 316 / Hastelloy C-276, Monel, PVDF, Teflon lining, etc.

Process Gas Filter

Dry Gas Filter

GP series – ASME Sec.VIII, Div. 1 code design, with or without stamp.

Size: 1”~12”

Pressure / temperature Rating: ANSI 150- 600 LB

Material: Carbon steel or stainless steel, NACE application can also be accommodated

Filter Separator

For high-efficiency separation of both solid and liquid contaminants.

Built to ASME code with stamp

Remove solids larger than 0.5~3 microns

99% and liquid particles 100% of 8 microns and 99% of 0.5~3 microns.

Metering & regulation stations, compressor stations, natural gas plants, Gas distribution systems, etc

Process Liquid Filters

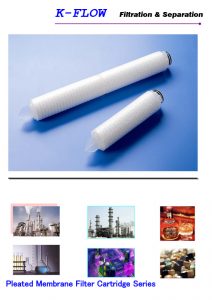

Cartridge Filters

ASME code design with or without stamp.

Housing – Carbon steel, stainless steel 304 / 316 / 316L / Teflon lining / FRP

Cartridges – Melt blown, string wound, pleated membrane, resin bonded, stainless steel 316.

Size: 3/4”~12”

Pressure / Temperature rating: ANSI 150~300 LB

Special material, pressure / temperature rating, accessories, upon request

Bag Filters

ASME code design with or without stamp. Single or multi-bags type.

Housing – Carbon steel, stainless steel 304 / 316 / 316L

Bags – polyester, propylene, Nomex, nylon, cleanable stainless steel, pleated, etc.

Size: 3/4”~12”

Pressure / Temperature rating: ANSI 150~300 LB

Special material, pressure / temperature rating, accessories, upon request

High Flow Filter

A combination the features of cartridge filter and bag filter, higher efficiency, lower disposal costs, lower maintenance costs, smaller filter housing, longer filter life, seal better & high dirt holding capacity.

ASME code design with or without stamp.

Housing – Carbon steel, stainless steel 304 / 316 / 316L

Cartridges – polypropylene, glass fiber, polyester.

Size: 2”~24”

Pressure / Temperature rating: ANSI 150~600 LB

Special material, pressure / temperature rating, accessories, upon request

Air & Gas Filter

Particulates and coalescing filtration.

Design code: ASME Sec. VIII, Div.1, latest edition with or without stamp.

Pressure rating: Upon requested

Material of housing: Carbon steel, stainless steel 304, 316L, etc.

Material of element: Polyester, micro-glass fiber, Nomex, Sintered stainless steel, etc.

Micron rating: Nominal or absolute, from 0.3 to 10 micron

Automatic Self-Cleaning Filters

ABF Brush Type

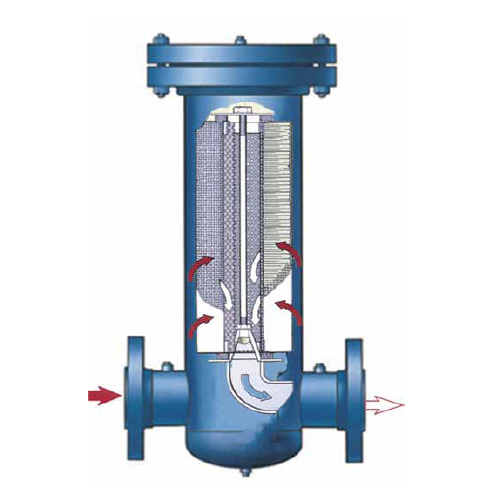

ABF Self-cleaning filter is designed with wedge (V) wire screen and self-cleaning by the rotating brush to remove debris on the surface of the screen.

It works continuous without interruption and no maintenance and running parts required

Size: 8”~24”

Material: Stainless steel 304, 316L

Filtration rating: 200 /300/500 /800/1000 / 2000 Micron

Special material, sizes, rating & explosion proof grade upon request

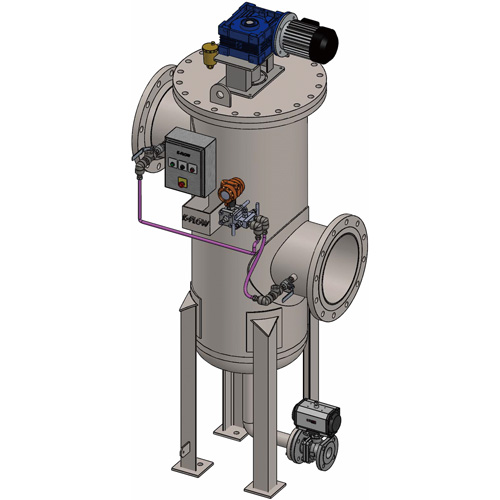

SCF Scraper Type

SCF Self-cleaning filter is designed with wedge (V) wire screen and self-cleaning by the rotating scraper or brush to remove debris on the surface of the screen.

It works continuous without interruption and no maintenance and running parts required

Size: 2”~16”

Material: Stainless steel 304, 316L

Filtration rating: 50 / 100 /150 /200 /300/500 /800/1000 / 2000 Micron

Special material, sizes, rating & explosion proof grade upon request

ABW Back-Flush Type

ABW Self-cleaning filter is designed with multi-cartridge wedge (V) wire screens and self-cleaning by the back-flushing to remove debris on the surface of the screen.

It works continuous without interruption and no maintenance and running parts required

Size: 4”~36”

Material: Stainless steel 304, 316L

Filtration rating: 50/75/100/200/250/300/500 Micron

Special material, sizes, rating & explosion proof grade upon request

Aviation Fuel & Oil Filtration and Separation

Micro-filter

K-Flow aviation micro-filter are designed to continuously remove fine particles such as rush, dirt, sand and pipe scale from aviation fuel systems. These highly efficient micro-filter are used at refineries, bulk fuel depots, transfer stations and airports, predominantly prior to filter/water separators to protect and prolong coalesce element life.

Design code: ASME Sec. VIII, Div.1 & API/IP 1590 latest edition.

Nominal micron rating: 0.5 ~ 30 micron, etc.

Maximum differential pressure: 1.5 bar

Admissible operating temperature: -30 ~ +80 ℃

Applications: Jet fuels / Diesel fuels / Light oils

Construction: Carbon steel or stainless steel

Options: ASME U stamped, Differential pressure indicator & Switch & Transmitter, Sampling probe, Automatic air vent with check valve, Pressure relief valve, Drain valve.

Filter water separator

K-Flow filter water separators is a vessel containing filter / coalesce and separator elements that continuously removes dirt and water from aviation jet fuel / diesel / light oil to levels acceptable for servicing modern aircraft and vehicles. A filter water separator can have either a vertical or a horizontal configuration and multiple stages. Vessel are designed and built in accordance with the strict engineering guidelines and pressure vessel regulations.

Design code: ASME Sec. VIII, Div.1 & API/IP 1581 lately edition.

Nominal micron rating: 0.5 ~ 25 micron, etc.

Maximum differential pressure: 1.0 bar (15 psi)

Admissible operating temperature: -30 ~ +80 ℃

Applications: Jet fuels / Diesel fuels / Light oils

Construction: Carbon steel or stainless steel

Options: ASME U stamped, Differential pressure indicator & Switch & Transmitter, Sampling probe, Automatic air vent with check valve, Pressure relief valve, Sight glasses (level gauges), Water slug control valve, Rate flow control valve, Flange float pilot & automatic eater drain valve, Drain valve.

Clay Filter – CLF

CLF Clay filter is to remove unwanted surface active surfactants, colouring and other additives which maybe present from refining process or during transportation of Jet fuel.

CLF are normally installed in front of a FWS.

Internal coating acc. To MIL-C-4566 latest edition standard

Material: carbon steel

Design pressure / temperature: upon request/