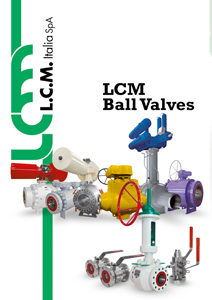

LCM Italia Spa

L.C.M. Italia S.p.A., established in 1986, is a fast-growing Company specialized in the design and production of API 6D and API 6A Floating and Trunnion Mounted Ball Valves for Oil, Chemical, Petrochemical, Pipeline, Natural Gas and Water Industries, Off-shore and On-shore Plants, all over the world.

LCM Italia designs and manufactures isolation quarter turn ball valves for the Oil & Gas and Petrochemical Industry.

Product range covers manual operated and actuated On-Off valves for several applications and fluids including: oil, gas, condensate, water, steam, various chemicals and aggressive media. All valves are designed by LCM Italia Engineering Department using the most advanced CAD & FEM software.

Ball valves may be configured according to project requirement for:

- Liquid, gas or multiphase fluids (including “foreign matters”).

- Clean or dirty stream conditions (abrasive/erosive).

- Non corrosive or corrosive service (c.a., CRA overlays as required).

- Sweet, sour or severe sour configuration (lethal service included).

- Low temperature (blow-down operable or not, arctic climes).

- High temperature process conditions (special polymeric seals).

Manually operated or actuated for normal operation or emergency function (e.g. MOV, XV, SDV, ESDV, BDV, HIPPS, SSIV).

- Special Applications

Specialized designs are available for the following applications:

- Cryogenic service (from GPL to LNG or other liquefied gas service).

- Extreme high temperature (non-polymeric seals design).

- Subsea applications (from shallow to deep water ROV operated).

- Installations (add this in above application tab page)

LCM ball valves may be installed in the following locations:

- Above ground (from desert to arctic climates, insulated or not).

- Underground installation (in pit or directly buried).

- On-shore or Off-shore (top-side or subsea installation & service).

Coating requirements and selection of valve and operator accessories are always based on project requirements.

- LCM Ball Valves

- LCM Brochure

- LCM Rising Stem Ball Valve

- LCM presentation March 2019

- LCM product catalogue

Trunnion-Mounted Ball Valves

API-6D valves are available in the following designs:

Side Entry, bolted body

2/3 PIECE FORGED

2 PIECE CAST

ALL SERVICES / FUNCTIONS / INSTALLATIONS

THE MOST FLEXIBLE & RELIABLE DESIGN EASY MAINTAINABLE AT SITE

NPS: 1⁄2”÷ 60”

CLASS: 150# ÷ 2500#

API‐6A: 2000 ÷ 15000 psi

Flanged, BW, CF, HUB ends

LT, CRYO, HT, SOUR, LETHAL, DIRTY, HP

DB&B, DIB‐1, DIB‐2

SOFT or METAL SEATED ALL BODY & TRIM METERIALS

ELASTOMERIC, THERMOPLASTIC SEALS

Welded Body

Welded Body

2/3 FORGED obtained from 2/3 pieces forged rings and/or spherical half bodies

For PIPELINES, UNDERGROUND, OFFSHORE, (SUBSEA) REDUCED WEIGHT, MINIMISED LEAK PATH, ENHANCHED STRUCTURAL INTEGRITY, NO MAINTENANCE

NPS: 12”÷ 60” TYPICAL

CLASS: 150# ÷ 900# (API‐6A: 2000 ÷ 5000 psi) BW, (FLANGED)

LT, SOUR, DIRTY, (HT)

DB&B, DIB‐1, DIB‐2 SOFT & PMSS, (METAL) SEATED CARBON STEEL, LTCS, (DUPLEX‐SS) ELASTOMERIC SEALS, (THERMOPLASTIC) EASY CLADDING OF FUNCTIONAL / WETTED SURFACES

Top Entry

CAST BODY

(HP & S‐SIZES) FORGED

MAINTENEABLE IN‐LINE / RISERS INCLUDED ALL FUNCTIONS & INSTALLATION MINIMIZED LEAK PATH

NPS: 2”÷ 60”

CLASS: 150# ÷ 2500# API‐6A: 2000 ÷ 15000 psi BW, FLANGED, HUB, C.F. SOUR, LETHAL, HP, LT, CRYO

DB&B, DIB‐1, DIB‐2 SOFT & METAL SEATED ALL BODY & TRIM MATERIALS ELASTOMERIC & THERMOPLASTIC SEALS.

Special Products

LCM Italia designs and produces also the following valve equipment:

Compact Modular

Compact Modular ball valves for independent process dual isolation

COMPACT MODULAR VALVES (DB&B)

DUAL ISOLATION WITH DOUBLE BALL BLOCK VALVES 3PIECE FORGED BODY

DOUBLE BLOCK & BLEED PROCESS ISOLATION MANUAL OR ACTUATED (MOV+ESDV) INTEGRAL OR FLANGED VENT VALVE FLEXIBLE, RELIABLE, COMPACT OFFSHORE INSTALLATIONS

NPS: 1/2” to 24” (larger upon request)

CLASS: 150# ÷ 2500# _ (API 6A available) FLANGED, HUB, CF ends HP, LT, SOUR, LETHAL, DIRTY,

FLOATING & TM BALL SOFT & METAL SEATED FULL RANGE OF SEALS AVAILABILITY SAMPLING AND INJECTION CONFIGURATION

Multi-way

Multi-way ball valves for switching or diverting function. Special products are configured in a modular construction taking advantages from the engineered trim components available for the basic products (show/add pics)

Multiways Forged or Cast Bolted Body

Taylor-made based on application floating or tm ball trims modular construction

Typical configurations:

3 Ways ‐ L or T Ports (1/4 TURN)

3 Ways – Y Pattern (1/3 TURN) 4/5 Wawys (2D or 3D Flow Pattern)

Diverting / isolating transflow or non‐transflow fit for purpose design & materials process based seating and seals config.

Rising Stem ball valves

Rising Stem Ball Valve, a new lcm product.

Friction free open and close for low maintenance and extended life.